http://bit.ly/2rtSt4l

New Zealand has an electricity system that is largely based on renewable energy. Because of our existing competitive advantage in wind and hydro power, many leaders in sustainable transportation predict hydrogen will only play a small role in New Zealand’s fleet.

A recent report by Z Energy shares a similar perspective, noting: “Z’s view is that hydrogen is more suitable for decarbonising high-utilisation, long-range use cases such as trucks, ferries, trains and buses, while battery electric will be the better choice for the shorter-range fleet.”

Adoption of electric vehicles (EVs) here is rapidly increasing — from 210 cars in 2013 to 10,000 in 2018. The benefits from EVs include lower emissions, quieter running, and the fact that they can act as a flexible storage solution for intermittent renewable energy.

And it is not just electric vehicles. The Global Battery Initiative, a World Economic Forum initiative, has called batteries a “backbone technology” in the transition from fossil fuels to a low-carbon future. Batteries — and particularly lithium-ion batteries — are powering anything from toys to cameras, e-scooters to e-bikes, trains and even electric vehicles.

But one of the major challenges faced by the industry is how to treat these batteries at the end of their useful life.

Further compounding this is the fact that New Zealand’s uptake of electric vehicles is heavily reliant on the introduction of second-hand vehicles. Cars are imported with semi-depleted batteries — they will reach the end of their useful life sooner than new cars.

This means the requirement to innovate to meet this challenge is especially front of mind for New Zealand — something that has been recognised by the Battery Industry Group (B.I.G), a cross-industry collaboration launched last week.

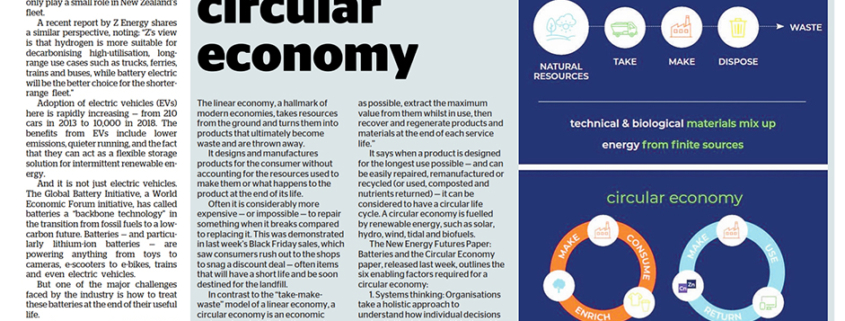

The group acknowledges the current “linear” system — extracting materials from the ground to make a battery, using the battery once and then putting the ‘waste’ battery into land fill — is not sustainable.

Made up of over 80 businesses — including a core delivery team of Vector, Eunomia Research & Consulting and WasteMINZ, with funding from Vector, EECA and the Motor Industry Association of New Zealand — the group will design solutions to reuse and recycle the large batteries found in electric vehicles or in stationary energy storage.

They note that a commercially sustainable model will require a shift across the entire system, and aim to propose a “circular” product stewardship scheme for end-of-use and end-of-life battery management to the Ministry for the Environment within the next 12 months. It will include recommendations on consistent safety guidance for the handling, storage and shipping of used large batteries.

Vector says the move acknowledges the important role businesses can play in not only front-footing the e-waste challenge, but also acts as a catalyst to accelerate New Zealand’s transition to a low-emission circular economy.

“Vector recognises that electrification of transport presents a significant opportunity to help

New Zealand achieve a zero-carbon future,” says Vector Group CEO, Simon Mackenzie.

“The research in the New Energy Futures Paper tells us that there will be between 500 and 1000 EV batteries coming to the end of their lives by 2020, potentially rising to 17,000 by 2025 and a staggering 84,000 by 2030.”

He says that while batteries will be key to powering New Zealand’s new energy future, they contain valuable materials that come at an environmental and social cost. It’s clear that we must work collaboratively with others to ensure we have a proactive, robust plan in place to make the most of battery capacity, as well as mitigating any risks from their disposal.

Leave a Reply

Want to join the discussion?Feel free to contribute!